AM-Smartenergy gives you energy. When it comes to medium and large decentralized power generation systems, more and more customers from industry, municipalities and energy supply rely on the specialist AM-Smartenergy.

The products selected by AM-Smartenergy are designed specifically for each customer.

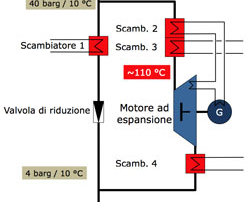

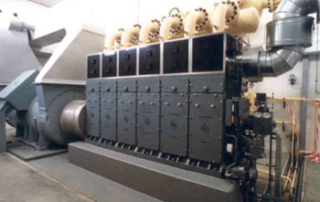

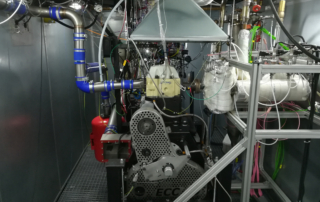

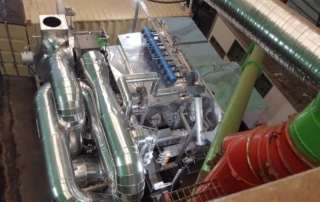

In the area of expansion machines for steam and gas, AM-Smartenergy has a diversified range of products, which can cover the most diverse applications.

Through the use of PtX technologies, electricity from renewable energy (ER electricity) can be used to produce synthetic energy sources with low CO2 emissions (energy fuels) and chemical raw materials. The starting point of the PtX technologies under consideration is the electrolytic production of hydrogen using renewable electricity. Hydrogen can then be used directly or stored. To open further areas of application, the resulting hydrogen can be further processed in additional processes with the help of other gases such as carbon dioxide (CO2) and nitrogen (N2). An advantage of the fuels obtained is that some of them can be used directly via existing infrastructures such as gas networks and filling stations or in the chemical industry.

Through the use of PtX technologies, electricity from renewable energy (ER electricity) can be used to produce synthetic energy sources with low CO2 emissions (energy fuels) and chemical raw materials. The starting point of the PtX technologies under consideration is the electrolytic production of hydrogen using renewable electricity. Hydrogen can then be used directly or stored. To open further areas of application, the resulting hydrogen can be further processed in additional processes with the help of other gases such as carbon dioxide (CO2) and nitrogen (N2). An advantage of the fuels obtained is that some of them can be used directly via existing infrastructures such as gas networks and filling stations or in the chemical industry.

The solutions proposed by AM-Smartenergy include both the low temperature and high temperature process.

The solutions proposed by AM-Smartenergy include both the low temperature and high temperature process.

So far, well-developed processes with low temperatures have been used such as alkaline electrolysis or electrolysis via proton exchange membranes (“PEM”). High-temperature processes may gain importance in the future. With solid oxide electrolysis (“SOEC”), which is a high temperature process, it is possible to achieve a high level of efficiency and thus a reduction in the electricity consumption of electrolysis, since the waste heat of other processes.

With the growing share of renewable energies, energy storage is becoming more and more important. Short term fluctuations can be compensated for by using many types of storage such as battery storage. In principle, different types of storage are suitable for compensating for seasonal fluctuations in electricity supply and demand, but certain technical requirements must be met. This implies that seasonal storage must have a high storage capacity. Furthermore, the energy losses do not have to be very high even in the case of storage for long periods of time.

With the growing share of renewable energies, energy storage is becoming more and more important. Short term fluctuations can be compensated for by using many types of storage such as battery storage. In principle, different types of storage are suitable for compensating for seasonal fluctuations in electricity supply and demand, but certain technical requirements must be met. This implies that seasonal storage must have a high storage capacity. Furthermore, the energy losses do not have to be very high even in the case of storage for long periods of time.

Change is the vital obligation of the industry and since 2012 AM-Smartenergy has been committed to innovation and progress.

Change is the vital obligation of the industry and since 2012 AM-Smartenergy has been committed to innovation and progress.

And if there was ever a need for slow change in the past, today the world is facing major environmental, sociological and technological challenges. A mix of natural gas and hydrogen is our solution to the future.

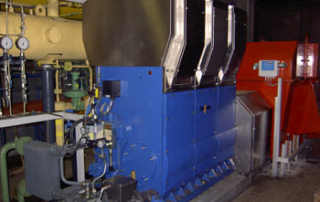

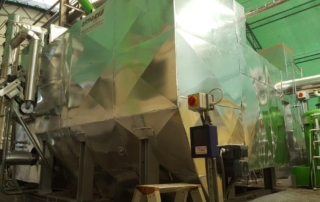

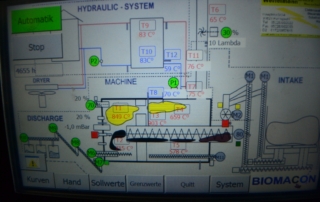

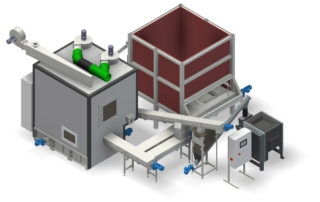

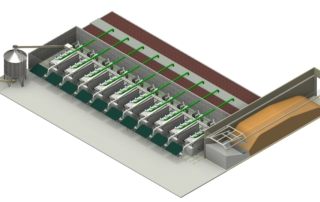

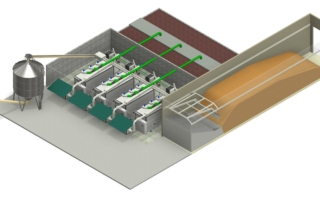

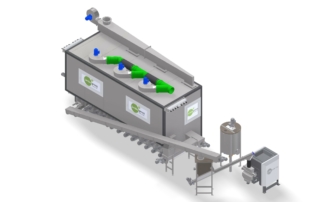

Due to its unique thermodynamic and fluid dynamic properties, fluid bed technology has established itself among industrial processes for utilizing solid and liquid production waste.

Due to its unique thermodynamic and fluid dynamic properties, fluid bed technology has established itself among industrial processes for utilizing solid and liquid production waste.

Thanks to the great variability of the process parameters, it is possible to optimize the process in an almost unlimited way.

The optimization of products and processes has become a competitive criterion in many branches of the industry.

At the top of the AM-Smartenergy agenda are the improvement in the use of zero km production waste for the food industry, for paper mills and for other industrial branches.

GET IN TOUCH.

CONTACT

VIA D’ANNUNZIO, 3

66020 SAN GIOVANNI TEATINO

Mobil Deutschland: +49 (0)173 6721148

Mobil Italia: +39 351 72 71 751

E-Mail: f.monteleone(at)am-smartenergy.eu